Product description

| Machine Configuration |

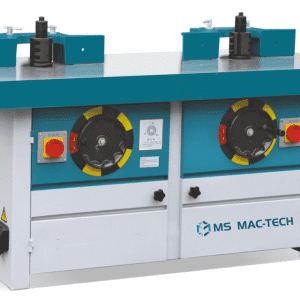

| This machine is specially designed for the sanding of the primer after the paint coating. It is suitable for all kinds of flat products, especially the flat wood. After the sanding of the machine, the paint surface is flat and not white.

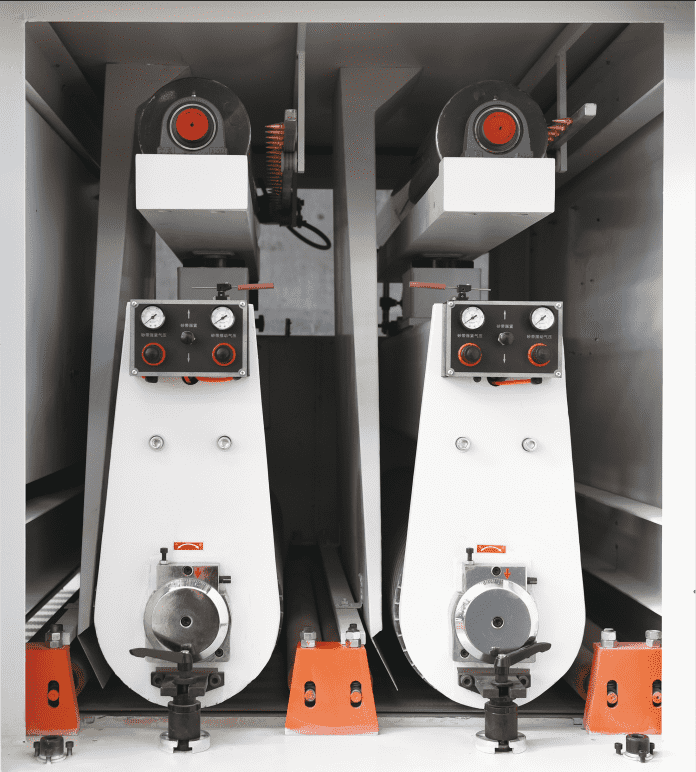

2, the fuselage steel plate bending parts welding, heavy weight, stable operation, and after annealing, will not be deformed for a long time. 3, the belt operation uses imported frequency converter frequency control, suitable for all kinds of paint characteristics, the belt centering uses photoelectric automatic control. 4. Feeding speed is controlled by stepless speed governor and stepless speed regulation. The lifting and lowering of the workbench adopts a four-column lifting structure without sloshing and small error. Double sanding primer sanding machine One sanding and one throwing sanding machine    5. The running rubber roller adopts 25SH rubber, which has large elasticity, clears the phenomenon of horizontal stripes and white edges, high precision and long service life. The device polishing wheel (optional), frequency control, high and low adjustable, will easily eliminate the horizontal stripes. 6. The conveyor belt adopts 3mm thick imported strong conveyor belt, which is wear-resistant and durable. 7. The automatic conveyor correcting mechanism of the conveyor belt automatically adjusts the running track of the conveyor belt during operation without manual adjustment. 8. The belt motor adopts the frequency conversion speed control system. Adjusting the speed control knob on the control panel can change the line speed of the belt. 9. The lifting and lowering of the workbench is realized by “↓↑”, which is displayed by the digital display thickness table. For small displacement, the handwheel adjustment on the shaft of the lifting motor can be rotated. 10. The conveying feeder consists of a conveyor belt running on the workbench, a continuously variable transmission, a tightening manual adjustment mechanism, and an automatic centering system for the cylinder and sensor control valve. The feed rate can be adjusted by adjusting the shift lever on the continuously variable transmission. 11. Safety device: There is an emergency stop button (self-locking) on the control panel, two photoelectric switches are installed on the left and right sides of the sand frame; the pressure relay operates when the pressure of the pneumatic system is insufficient, and a disc brake is mounted on the motor pulley to Guarantee quick brake stop in case of emergency. 12. The fault display light is installed on the control panel. If the air pressure is insufficient, the left and right of the belt will be out of control. 13, a unique vacuum device to make the vacuum effect better. Another customer needs to be equipped: 1, 50Hz, 380V three-phase power supply. 2. 0.5MPA gas source. |

| Model | MS-1R-1300/ MS-2R-1300 |

| Working Width(mm) | 30~1300 |

| Working Thickness(mm) | 2 ~110 |

| Feeding Speed (m/min) | 5-15 |

| Belt Size∮ | 1320*2200 |

| Min. Working Length(mm) | 300 |

| Sanding Roll Size∮ | ∮240 |

| Polishing roll size∮ | ∮200 |

| Work Voltage(mpa) | ≧0.55 |

| Wind Velocity(m/s) | 25~30 |

| Convey Power(kw) | 4 |

| Polishing roll power (kw) | 7.5 |

| Belt Power(kw) | 11 |

| Total Power(kw)of Double Heads | 27.1 |

| Total Power (kw) of Single Head | 15.92 |

| Machine Size(mm)of Double Heads | 2700×2100×2100 |

| Machine Size(mm)of Single Head | 1700×2700×2100 |

| Machine Weight(kg)of Double Heads | 2800 |

| Machine Weight(kg)of Single Head | 2600 |

Reviews

There are no reviews yet.