Product description

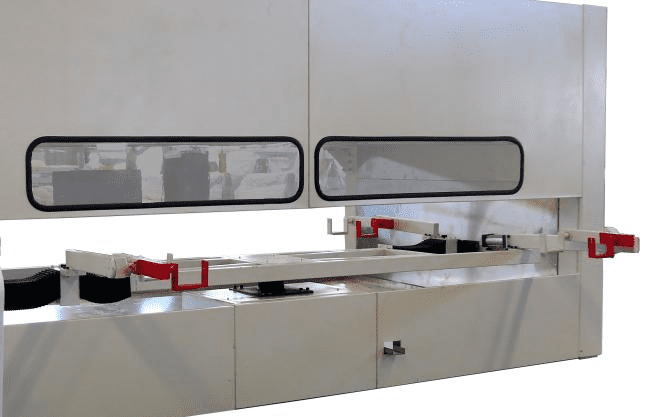

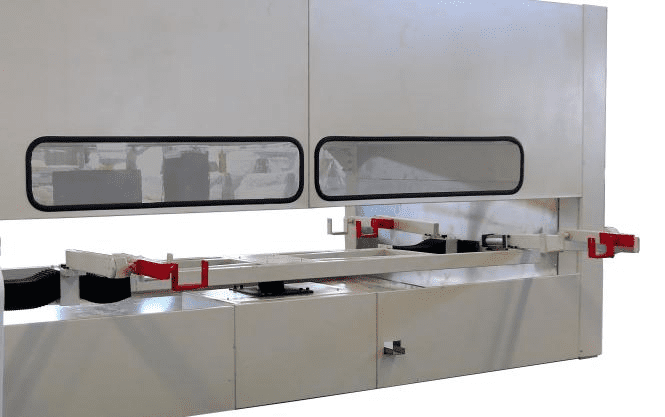

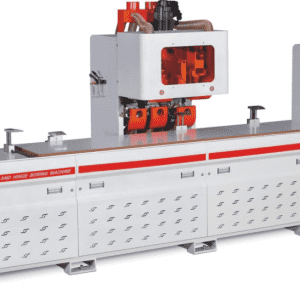

The CNC automatic painting machine is composed of manipulator (machine body), controller and servo drive system. It is a kind of man-made operation, automatic control, reprogrammable, and can complete various spraying work in three-dimensional space. It’s suitable for flexible production of multiple varieties and multiple batches. It plays an important role in stabilizing and improving the quality of paint spray, production efficiency, labor intensity, and rapid product replacement.

The CNC automatic painting machine does not replace the manual painting work in a simple sense, but a kind of anthropomorphic electromechanical device that combines the special features of people and machines.

It has the ability to quickly respond to the state of the environment, analyze and judge, and has the ability to work continuously for a long time, with high precision and resistance to harsh environments. It is an indispensable automatic painting equipment for the furniture manufacturing industry.

Characteristic:

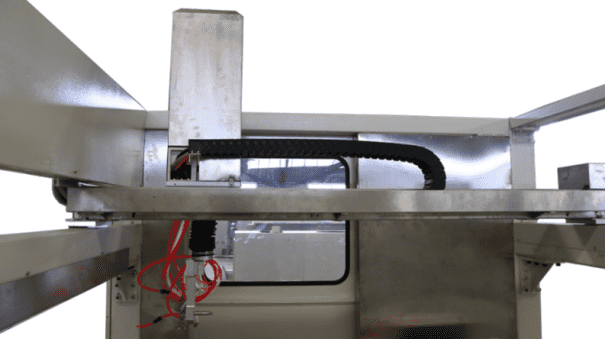

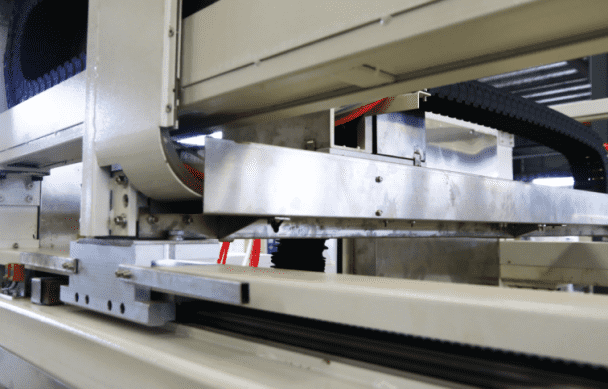

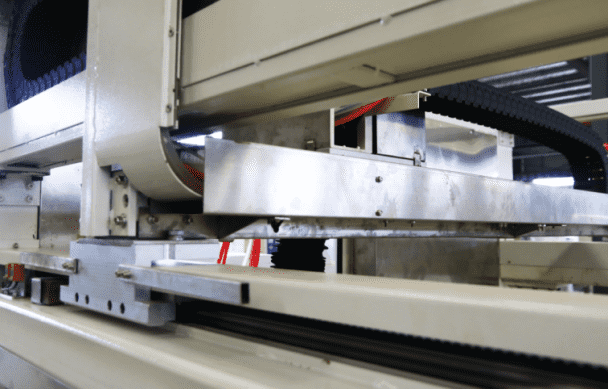

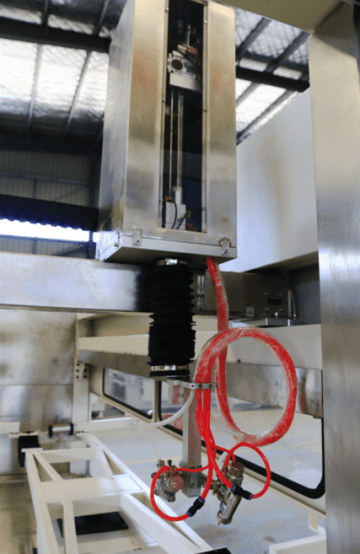

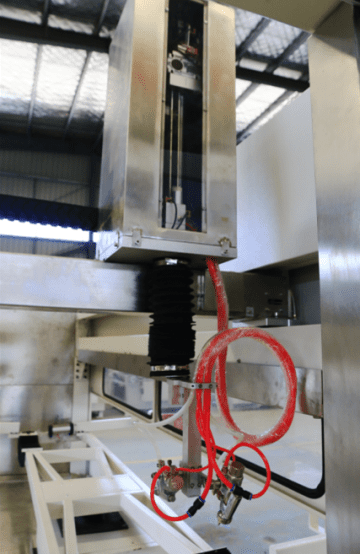

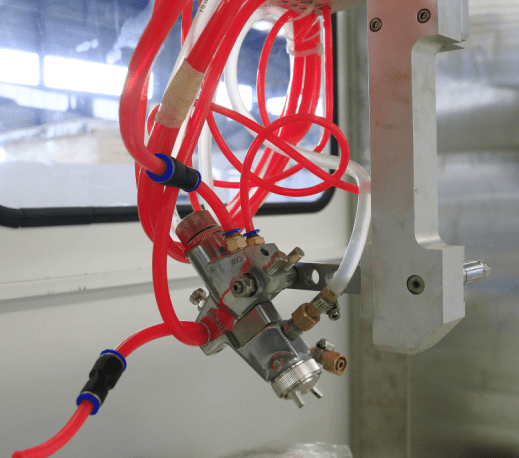

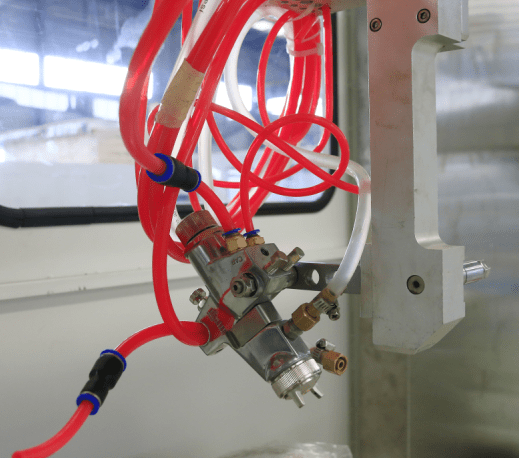

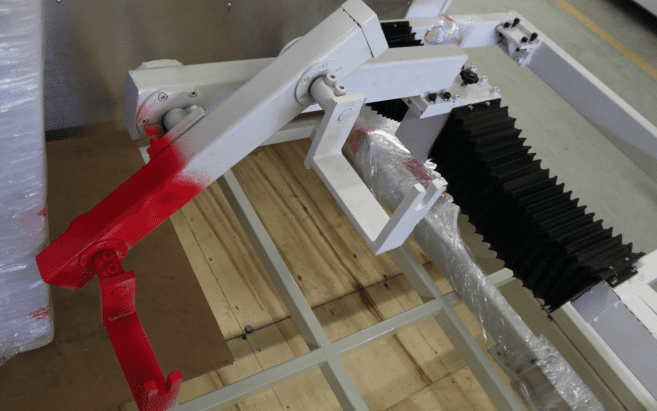

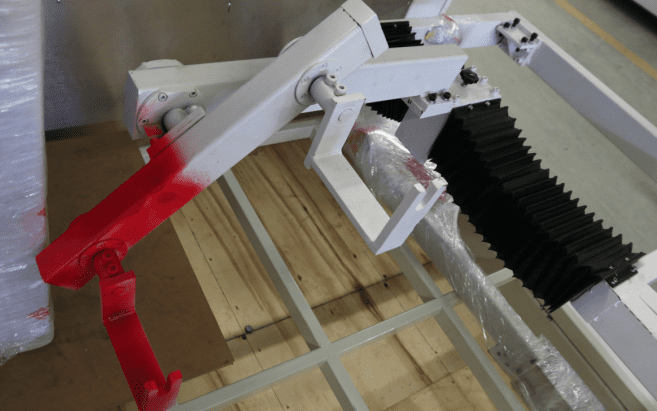

- The use of five-axis CNC spray paint machine structure, painting speed, spray gun can be multi-angle flexible rotation, fully realize the anthropomorphic painting method.

- The spray gun is controlled by the computer to move and turn on and off in any path within the maximum stroke range, so that the paint is even and the paint is saved. The program controls the spray gun for uniform painting in a cross-type motion.

- The four sides, profiled surfaces or arcs of the wooden door and the plate-type workpiece (large table) can be uniformly sprayed by a preset program.

- he machine is equipped with an automatic turning structure. It only needs to put the wooden door on the flip frame to realize the painting process of the wooden door. It does not need fixture assistance, saves operation time and is convenient to operate.

- Digital programming, by inputting the size parameters of the workpiece and the number of paintings, the painting program can be automatically generated, which is the real automation; the program can memorize 1000 different programs, which can be used for 1000 different specifications of the workpiece. Automatic CNC painting

| Technical Parameter | |

| Model | MS SM-1100 |

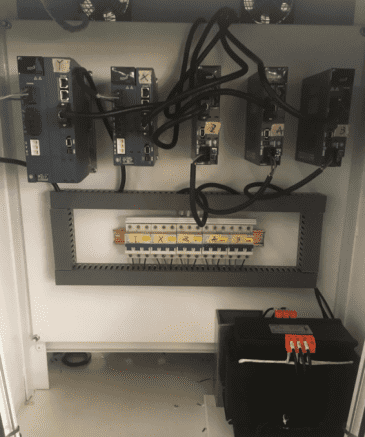

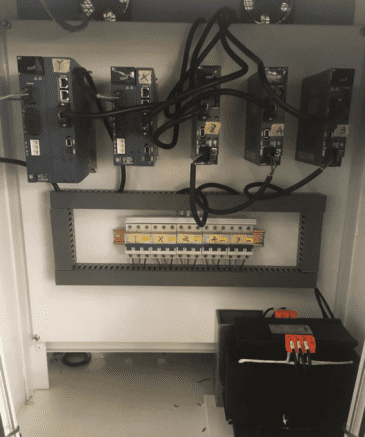

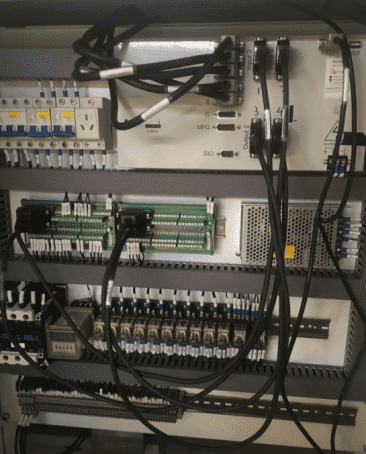

| Control System | Wantai |

| Servo Motor | China Huichuan |

| Flex Pendant | Wantai |

| Servo Controller | China Huichuan |

| Synchronous belt | Italy Max |

| Spray guns | Mingli Taiwan |

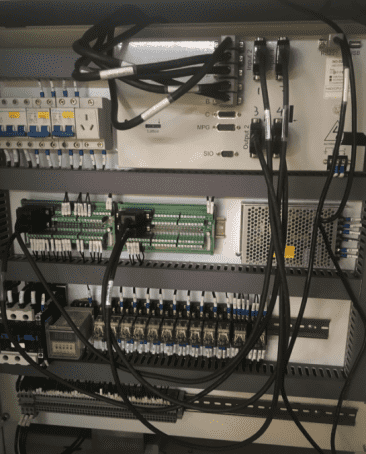

| Electric component | France Schneider |

| Frequency converter | Taiwan |

| Servo cable | Herou |

| Water curtain, positive pressure pressure wind | China |

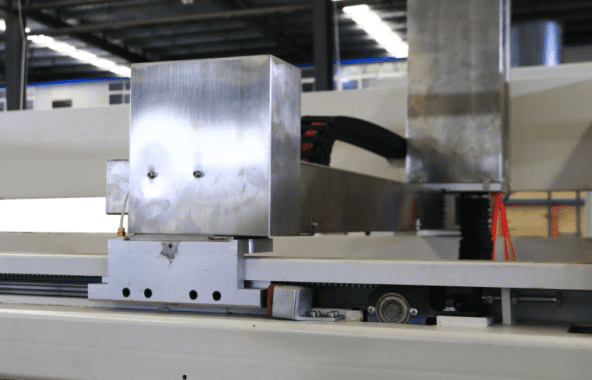

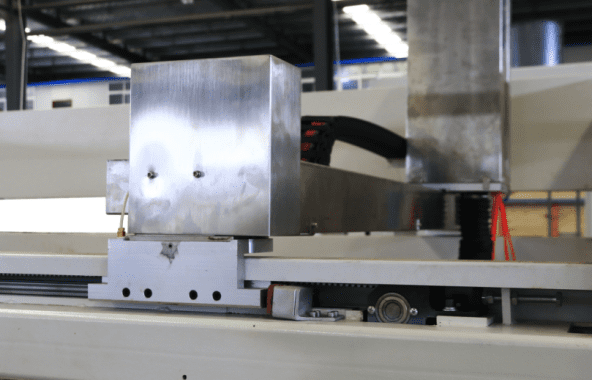

| Lead Rail | Taiwan TBI |

| pneumatic | Taiwan AirTAC |

| Working Width | 1.1M |

| Working Length | 2.4M |

| Max. Working Thickness | 100mm |

| Lifting range of gun frame | 0.35M |

| Main Electrical Components | France Schneider |

| Human Machine Interface | Taiwan |

| Servo Cable | Germany HELUKABEL |

| Guide Rail | Taiwan HIWIN |

| Spray Gun Caliber | 1.5 |

| U axis of rotation | 0-360 degree |

| Spray Gun Angle | 20-100 degree |

| Rotating platform | 180 degree exchange |

| href=”javascript:;” Working width | 1050mm |

| Working length | 2500mm |

| Working thickness | 150mm |

| Working Air Pressure | 0.6MPA |

| Speed of spray gun | 0-1800mm/s |

| Lifting range of gun rack | 350mm |

| Load bearing | 150KG |

| Type of paint | PE,PC,PU, UC,XU,UV, Water-based paint |

| Application | Door, Furniture, cabinet |

| Weight | 2200KG |

| Total Power | 380V/4KW |

| Air flow | 700-900 L/min |

| Servo motor power | 4KW |

| Gas consumption | 700-900 L/min |

| Power supply | 380V50HZ (three-phase 4-wire) |

| Max. processed size | 2500*1050*150mm |

| Spray Guns | 2pcs |

| Machine Size | 4700* 2300 * 2500mm |

Reviews

There are no reviews yet.