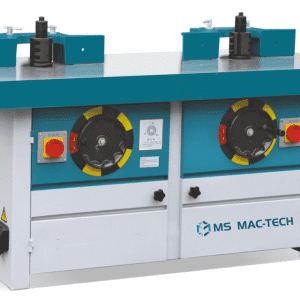

Product description

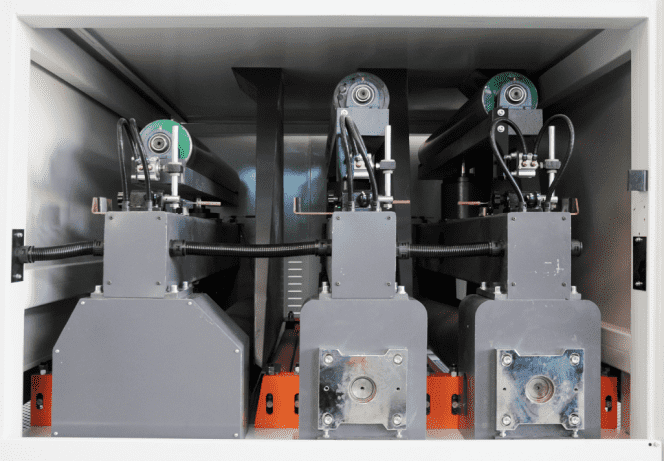

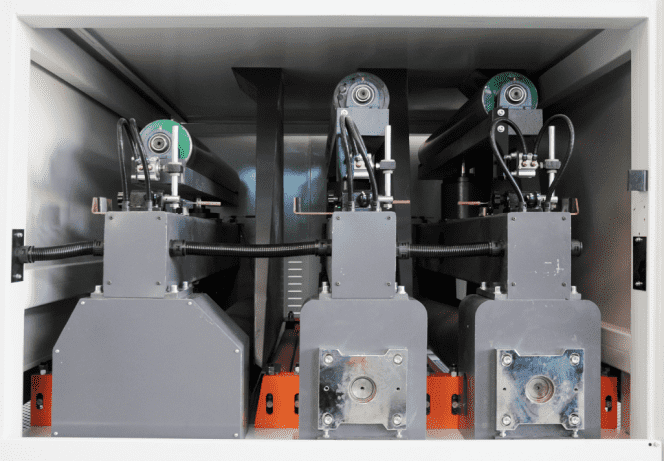

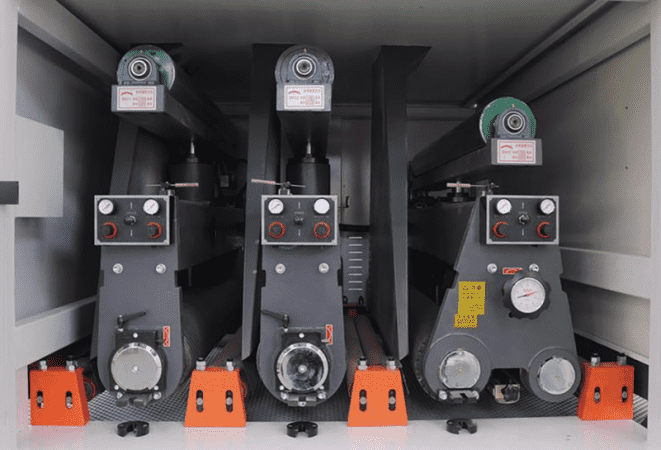

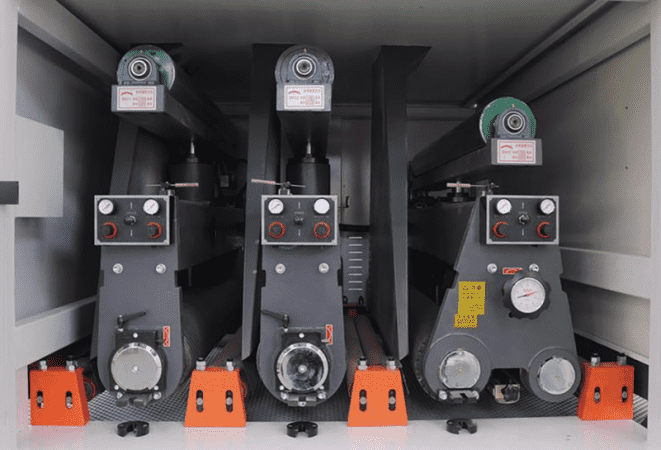

| Machine Configuration |

| The fuselage steel plate bending parts are welded, the weight is large, the operation is stable, and it is annealed, and will not be deformed for a long time.

2. Feeding speed is controlled by stepless speed governor, stepless speed regulation. The lifting and lowering of the workbench adopts a four-column lifting mechanism without sloshing and small error.

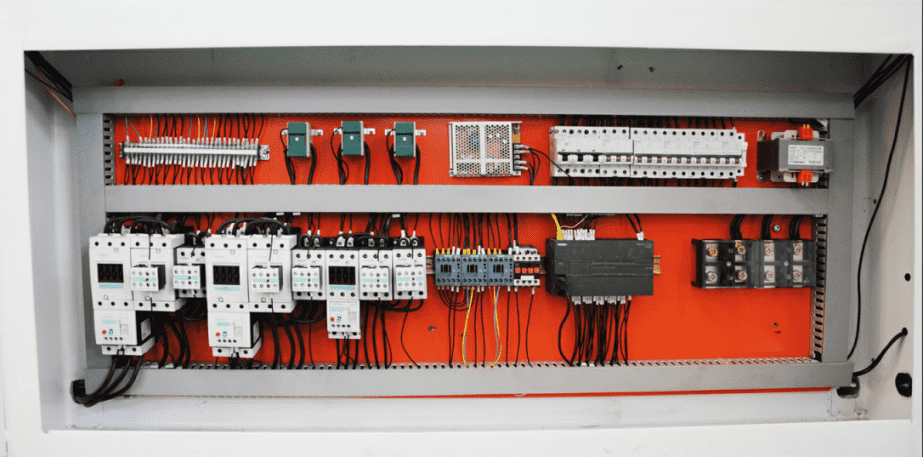

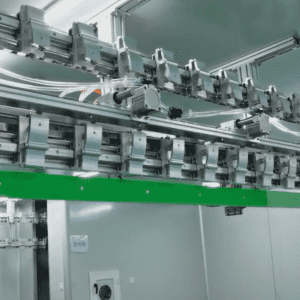

3. The front belt motor is started by “Y/△”, and the conversion time is set by the time relay in the electric control box. 4. The lifting and lowering of the workbench is realized by “↓↑”, which is displayed by the digital display thickness table. For small displacement, the handwheel adjustment on the shaft of the lifting motor can be rotated. 5. The photoelectric belt automatic control is adopted in the centering of the belt before and after the machine. The front sand roller adopts an adjusting mechanism, and the eccentric shaft is driven by a cylinder, and can be raised without the need of the sand roller.     6. The conveying feeding device consists of a rubber conveyor belt and a continuously variable transmission running on the workbench, a tensioning manual adjustment mechanism and an automatic centering system for the cylinder and the sensor control valve. The feed rate can be adjusted by adjusting the shift lever on the continuously variable transmission. 7. Safety device: There is emergency stop button (self-locking) on the control panel, two photoelectric switches are installed on the left and right sides of the sand frame; the pressure relay operates when the pressure of the pneumatic system is insufficient; the disc brake is mounted on the motor pulley to Guarantee quick brake stop in case of emergency. 8. The fault display light is installed on the control panel. If the air pressure is insufficient, the belt will be out of control and over-travel. 9, a unique vacuum device to make the vacuum effect better.

Another customer needs to be equipped: 1, 50Hz, 380V three-phase power supply. 2, 0.5MPA air source supply |

| Model | MS-3RP-1300 |

| Working Width(mm) | 1300 |

| Working Thickness(mm) | 2.5~80 |

| Feeding Speed (m/min) | 6~38 |

| Sanding Roll Size∮ | ∮240 |

| Work Voltage(mpa) | ≧0.55 |

| Wind Velocity(m/s) | 25~30 |

| Convey Power(kw) | 4 |

| Belt Power(1)kw | 37 |

| Belt Power(2)kw | 22 |

| Total Power(kw) of JXY-3RP-1300 | 96.87 |

| Machine Size(mm) of JXY-3RP-1300 | 2100×2400×2100 |

Reviews

There are no reviews yet.