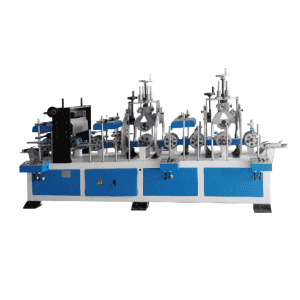

Product description

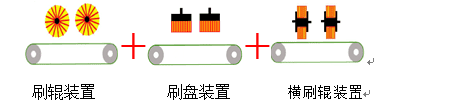

Combination: can be adjusted according to requirement, location and qty.

| Machine configuration |

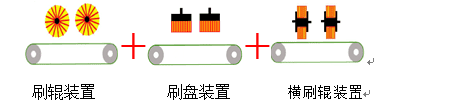

| 1、The machine made up of frame, the infeed conveyor means, lifting table means, the brush disk device, the brush roller means, brush roller brush disc separate lifting device, the brush disc brush roller oscillating means, electrical control means and automatic, the suction device and the like composition.

2、Discs with quick connectors can quickly replace the disc, steering is adjustable, forward and reverse can be adjusted to meet the different requirements of the sanding shape. 3、Worktable electric lift different thickness of sanding material to adjust faster, more effort. 4、Cast iron roller seat pull-down spring, to extend the service life. 5、Grinding head group can be adjusted separately for lifting the height of different shapes, can be individually adjusted to achieve the best sanding effect. 6、All grinding head speed is independent of frequency control for different material shapes, the freedom to choose the best sanding speed. 7、Low pressure roller spacing, short material into the compact roller spacing, can provide a shorter sanding length. 8、Digital control panel free to set the processing height, easy to operate, easy to learn and training. 9、Round rod linear guide control swing lasting long life, good stability. 10、Granite workbench is not deformed, good stability. 11、Double-row facing brush for horizontal sanding better. 12、Brush roller spiral structure to reduce the sand cutting marks. 13、Using one machine structure The body is more compact, small footprint. Operating Voltage: 380V,50Hz |

|

Technical Parameters |

|||

| model | MSPS-1300 | model | MSPS-1300 |

| Processing width | 20~1300mm | Horizontal brush roller motor | 2.2KWX2 |

| Processing thickness | 5~100mm | Brush motor | 1.5KWX2 |

| Processing sheet length | Not less than 390 mm | Brush roller motor | 3 KWX2 |

| Horizontal

Brush roller speed |

100—900r/min | Conveyor belt motor | 3KW |

| Horizontal brush roller number | 10 | Workbench lift motor | 0.55KW |

| Brush speed | 40—440r/min | Grinder alone lift motor | 0.18 KWX4 |

| Brush the number | 10 | Oscillation motor | 0.55 KWX2+0.25 KWX2 |

| Brush roller

speed |

70—780r/min | Total motor power | 19.27KW |

| Number of brush rollers | 2 | working pressure | ≥0.5Mpa |

| Conveyor speed | 2.5~12.5m/min | Dust volume | 12000m3/h |

| Horizontal brush roller

diameter∮300 |

Emery cloth 20 / month | Vacuum port diameter | ∮150mmX6 |

| Brush disc

diameter∮180 |

Emery cloth 18 / month | Dimensions | 3600*2200*2050mm |

| Brush roller

diameter∮300 |

Emery cloth 20 / month | Weight | approximately 4500KG |

|

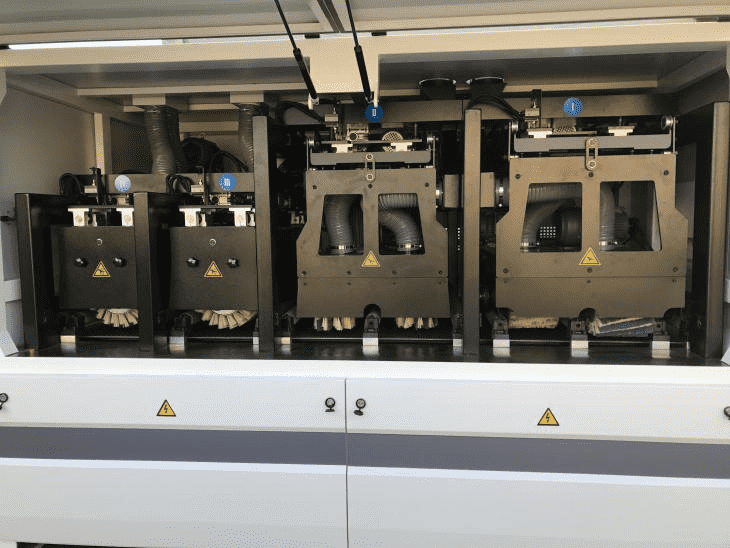

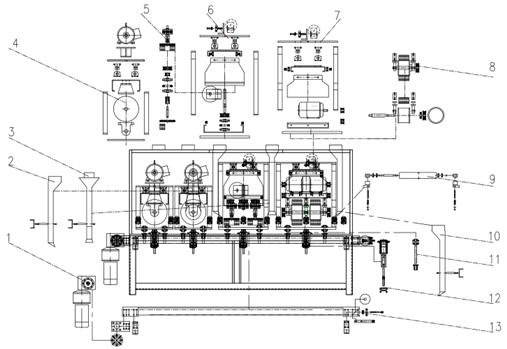

Main part description |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Reviews

There are no reviews yet.